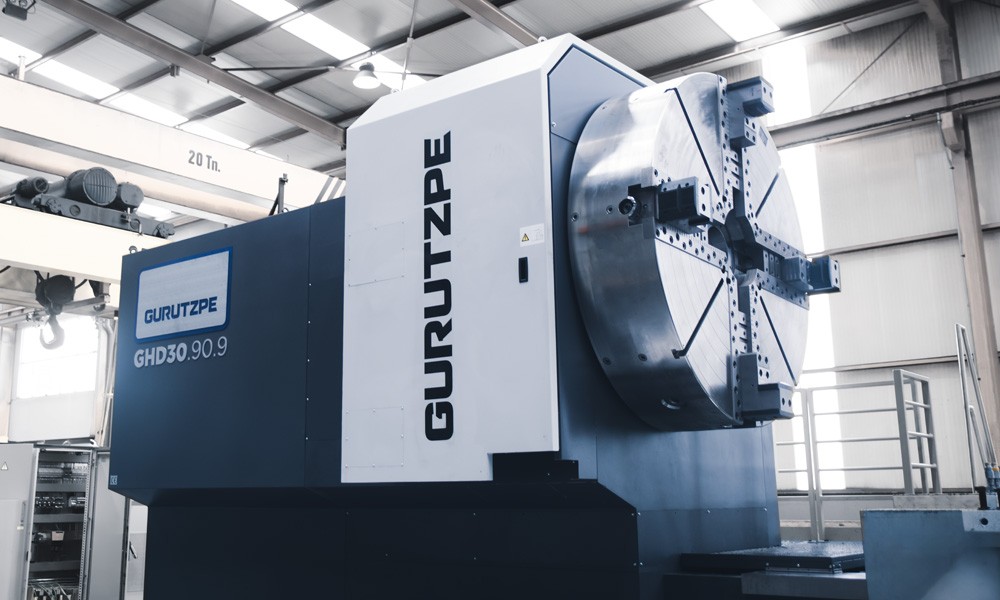

Large-Scale Machining at Gurutzpe Turning Solutions

Gurutzpe relies on HELUKABEL pre-assembled cables and drag chains

The Spanish mechanical and electrical engineersat Gurutzpe Turning Solutions rely on custom cables and drag chains from HELUKABEL for their large-scale CNC lathes. The result? Significantly reduced installation times, error-free setup, and the highest reliability worldwide.

When it comes to high-precision machining of large parts, customers trust Gurutzpe Turning Solutions. Founded in 1955 in the Basque city of Deba, the company specialises in the development and manufacture of large-scale CNC lathes. Its customers come from diverse sectors, including steel and energy production, shipbuilding and railways, aeronautics and astronautics, and the paper and pulp industry.

Ninety-five percent of Gurutzpe’s production is destined for international clients in countries such as the United States, China, Germany, and France. "Wherever maximum precision and reliability are required in the machining of large and heavy parts, you will find our machines," proudly states Joaquin Orbegozo, Director of Electrical Engineering.

Designed for transport

Gurutzpe CNC lathes are complex systems with intricate automation systems that must be connected to a central control system. Due to their size, they are disassembled into their individual components for transport and reassembled at their destination. This means that all electrical connections must be designed to be able to be disconnected and reconnected quickly and safely.

"For machines with travels of up to 20 metres and environments where oil, metal chips, or other loads are encountered daily, we need robust, flexible, and standardised solutions," says Mechanical Designer Andoni Elosua. Drag chains are a fundamental component in protecting cables that are constantly moving and subjected to mechanical loads such as bending, tension, and abrasion.

Tailor made solutions from a single source

For more than three decades, Gurutzpe has relied on the expertise of Urkunde, the Spanish subsidiary of HELUKABEL. This collaboration grew from the supply of electrical cables and wiring into a partnership, and today, Urkunde offers complex, preassembled drag chain solutions, precisely tailored to the needs of each machine.

For their current project, they are using closed hybrid and steel drag chains from the HELUKABEL HELUCHAIN HYBRID LINK 4-PL and HELUCHAIN STEEL LINK 4-SL ranges. Even in harsh environments, they are strong, durable, and reliable, protecting the internal cables from external influences such as dust and chips. Their stability even prevents the cables from being crushed or kinked during movement, improving operational safety and minimizing the need for maintenance.

Inside the drag chains, you will find the TOPSERV 109 PUR servo motor cable, designed to reliably transmit power to and from servo motors. These highly flexible cables are oil resistant and ideal for the continuous motion of machine tools. The HELUCHAIN MULTISPEED 522-TPE UL/CSA control and connection cable was also specifically developed for the highly dynamic movements of drag chains. It ensures reliable power transmission over long distances, even with rapid accelerations.

To ensure precise signal transmission, the TOPGEBER 512 PUR cable features a polyurethane sheath that offers high mechanical resilience and resistance to oils, coolants, and lubricants, which are decisive advantages in harsh industrial environments. PROFINET cables manage industrial communication between control systems and peripherals and are designed for reliable, real-time, and interference-free data transmission over long distances.

These modules are delivered pre-assembled, so the only step left after delivery is to connect them. "This not only saves us valuable time but also prevents wiring errors and improves the traceability of our facilities," explains Mr. Orbegozo.

Improving installation efficiency

Thanks to these pre-assembled drag chains, installation times at Gurutzpe have been reduced by approximately 40 per cent. The straightforward construction and clear labelling of all connections have significantly improved the traceability of wiring. Having an impressive start-up error rate of zero is an important factor for upholding tight delivery deadlines. "Especially for complex projects such as this, our success relies on being able to closely collaborate with HELUKABEL," says Mr. Orbegozo.

About Gurutzpe Turning Solutions

The Spanish mechanical engineering company Gurutzpe supplies horizontal turning machines for machining strategic parts in the most demanding industrial sectors. In recent decades, Gurutzpe has delivered more than 6,000 machines worldwide. Today, the company is part of the INZU Group and has approximately 500 employees—more than 70 of whom work in the lathe division.